I-rotary kiln yezinto zokwakha kunye ne-metallurgy

Iimpawu zobuGcisa

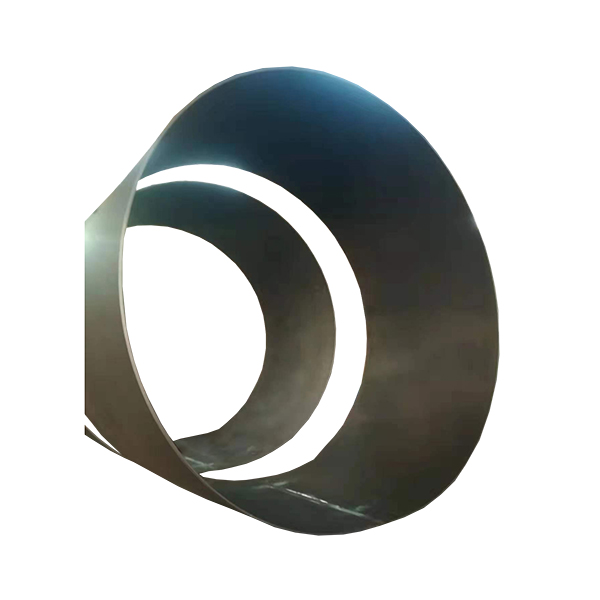

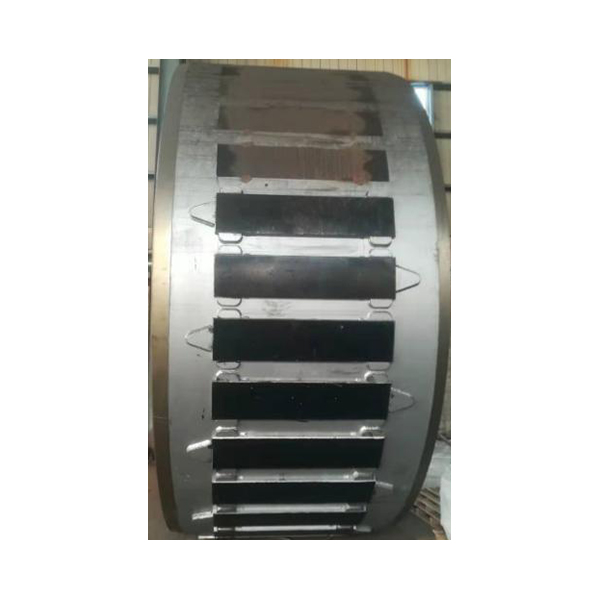

I-rotary kiln sesona sixhobo sibalulekileyo kwishishini lemathiriyeli yokwakha, enokuthi yohlulwe ibe yi-sement kiln, i-metallurgy kiln kunye ne-chemical kiln kunye ne-lime kiln ngokwezinto ezahlukeneyo.Iziko lesamente lisetyenziswa ikakhulu ukwenza ukubalwa kweclinker yesamente, enokuthi yohlulwe ibe yiziko eyomileyo yesamente kunye neziko lesamente emanzi.I-Metallurgical kiln yekhemikhali ye-Metallurgical isetyenziswa ikakhulu kushishino lwesinyithi, kwiplanti yentsimbi esetyenziselwa ukugcadwa kwemagnethi yentsimbi ekrwada kunye ne-oxidation yokugcadiswa kwechromium kunye ne-nickel ore;kwisityalo esilahlayo esisetyenziselwa ukosa umhlaba we-aluminiyam i-vanadium;kwisityalo se-aluminiyam esetyenziselwa ukutshisa i-clinker, i-aluminium hydroxide;kwisityalo sekhemikhali esisetyenziselwa intsimbi ekrwada yechromium kunye nomgubo wechromium kunye nezinye iiminerali.I-kiln yekalika isetyenziselwa ukubalwa kwekalika esebenzayo kunye ne-dolomite etshiswa ukukhanya kwisityalo sentsimbi kunye nesityalo se-ferroalloy.Izinto zeqokobhe le-rotary kiln zidla ngokuba yi-235C, 245R, 20G, njl njl. Ubukhulu buyohluka ukusuka kwi-28mm ukuya kwi-60mm.Okwangoku, eyona dayamitha yeqokobhe elikhulu yi-6.1m (kwi-rotary kiln ye-10000t/d line).

a.Inkqubo yokwenziwa ekwinqanaba eliphezulu:

● Uyilo olwenziwe ngokwezifiso: Igobolondo ehlukeneyo yobubanzi, ubukhulu kunye nobude bungenziwa ngokweemfuno zomthengi.Inokwenziwa ngokupheleleyo okanye inxalenye.

● Inkqubo yokuvelisa: I-Machining welding groove kunye nomatshini wokugaya;I-Welding ene-arc ye-arc ezenzekelayo, enenkangeleko egudileyo kunye nentle;Ngaphakathi ixhaswa ngu Union Jack iflegi imilo ukuthintela deformation;Ngomatshini omkhulu wokuqengqeleka, ukuchaneka kwe-cylinder kuphezulu.Umphezulu utshizwe ngepeyinti yokunqanda umhlwa kunye nepeyinti enqanda umhlwa.

● Ukulawulwa komgangatho: Lawula ngokungqongqo inyathelo ngalinye kwinkqubo yokuvelisa, jonga ngokungqongqo ukujikeleza, ukuhambelana kunye nezinye izalathisi zokuqinisekisa ukuba ukunyamezelana kuyahlangabezana neemfuno.

b.Ukuhlolwa okungqongqo:

● Ukuxilongwa kwe-welding joint flaw kufuneka kwenziwe kwimveliso nganye ukuqinisekisa ukuba akukho mingxunya yomoya, imingxuma yesanti, i-slag inclusions, ii-cracks, i-deformation kunye nezinye iziphene ze-welding.

● Imveliso nganye ilinganiselwa kwizalathiso ze-axial kunye ne-radial ukuqinisekisa ukunyamezelwa kwe-dimensional kuyahlangabezana nemigangatho yokwenziwa kweshishini.

Isalathiso sokusebenza

Akukho ngaphantsi kwemigangatho yoshishino.

Isicelo

Isetyenziswa ngokubanzi kwiziko elijikelezayo lamandla, izixhobo zokwakha kunye neshishini lesinyithi.